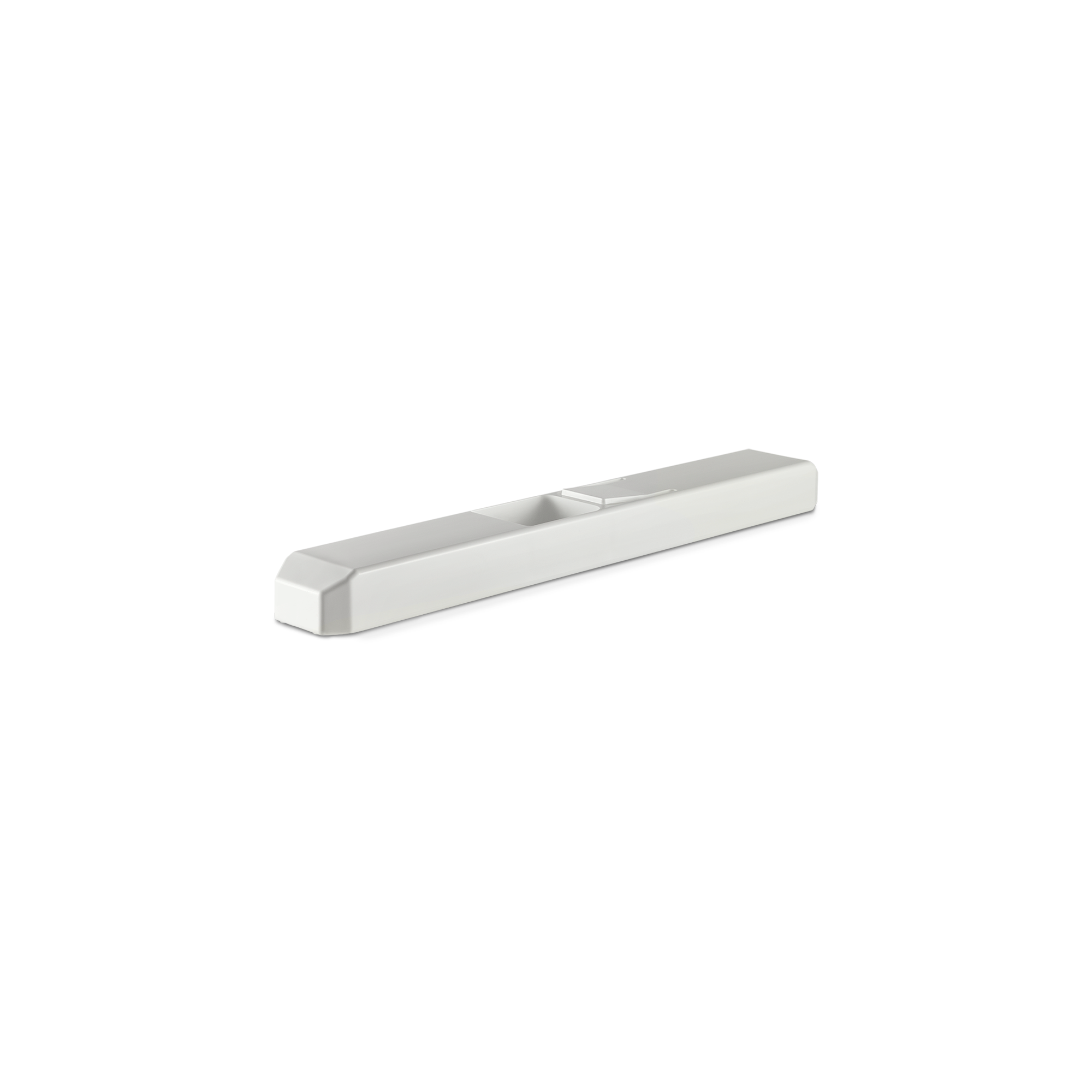

Surface Extension Sleeve

Traditional shelving isn’t designed to grow, it doesn't matter if you built it yourself, bought a wall shelving system, or use floor standing storage racks. The moment you need more length, you pay in time: unloading the shelf, removing hardware, buying more material, cutting to exact size, and adding new supports to prevent sag. Splicing is worse—most brackets are too narrow for a confident joint, so you end up stacking fixes (plates, extra screws, added brackets) that cost time (your time is valuable), clutter the wall, and you're lucky if the result looks clean.

And it’s not just “storage shelving.” The same extend-the-run problem shows up everywhere you could use a horizontal surface: workbenches, kids desks, home office workspaces, console tables, laundry folding counters, gear prep stations—anywhere you want to grow a surface without rebuilding it.

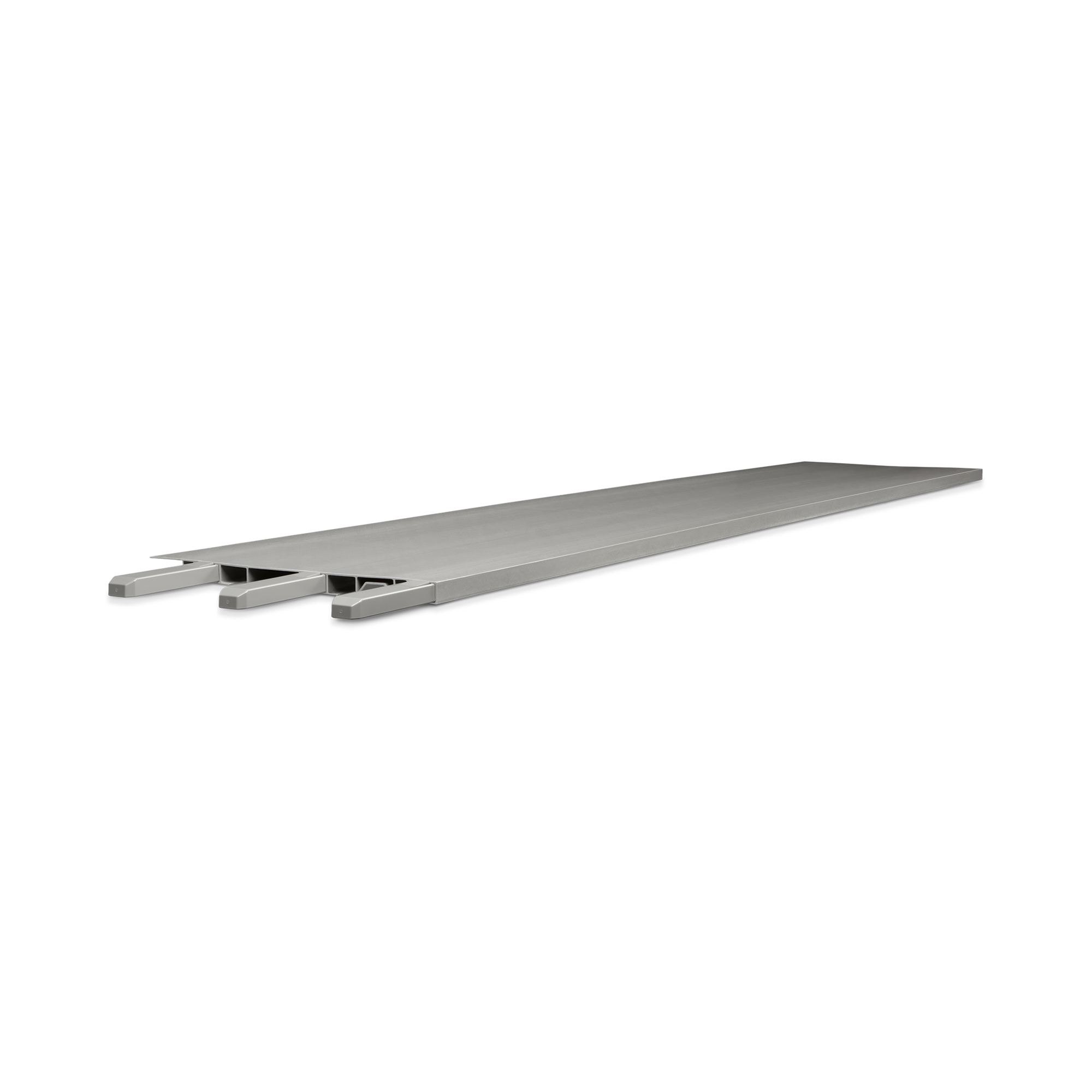

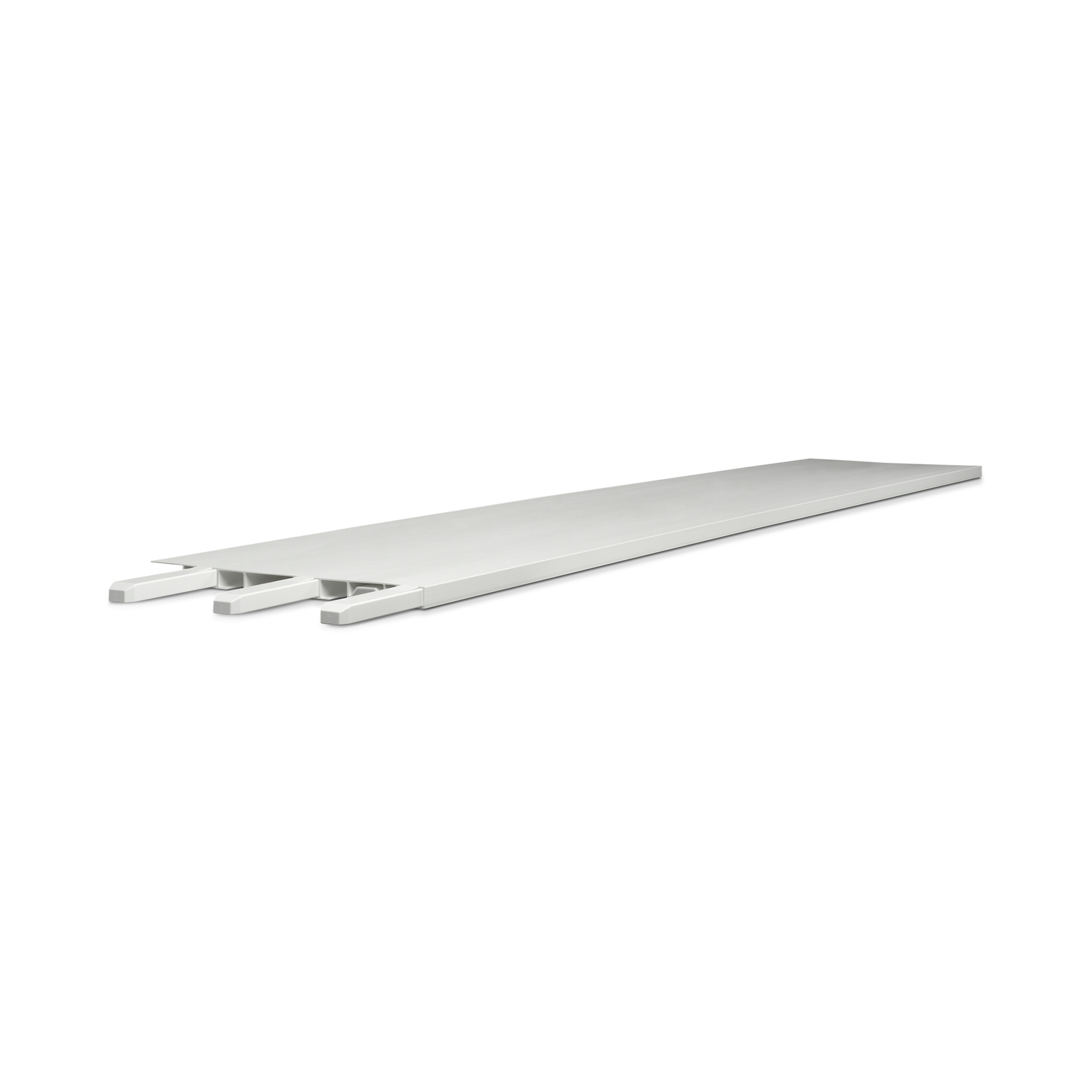

The Toden Extension Sleeve eliminates this ridiculous friction. All Toden parts are precision-fit and the Extension Sleeve is not different, featuring a built-in connector that slides into the dedicated hollow cores inside a Toden Surface and supports the connection internally. No cutting. No mending plates. No custom joinery. No tools. You keep a clean, continuous surface, the under-shelf channel stays usable, and your setup stays modular—so extending a run feels like an upgrade, that's completely doable, and not a remodel. Best of all, you can do it with the previous Toden surface already installed, loaded with containers too!

Key benefits

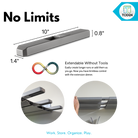

- Extend without cutting wood, laminate, or metal

- No ugly, weak splices that demand extra brackets at the seams or plates

- Tool-free sleeve install into dedicated cores (brackets mount normally)

- Internal seam support for a cleaner, more confident joint (maintains load ratings)

- Keeps the under-shelf channel usable for Toden snap-in accessories

- Makes surfaces expandable: shelving, benches, desks, and workstations

Best uses

- Garage and utility shelving you want to extend later

- Workbenches that grow with tools, bikes, skis, or projects

- Kids desks / homework stations that evolve with age and needs

- Home office surfaces where you want one continuous run

- Console tables + entry drop zones that need “just a little more” length

- Laundry folding counters and workshop prep surfaces

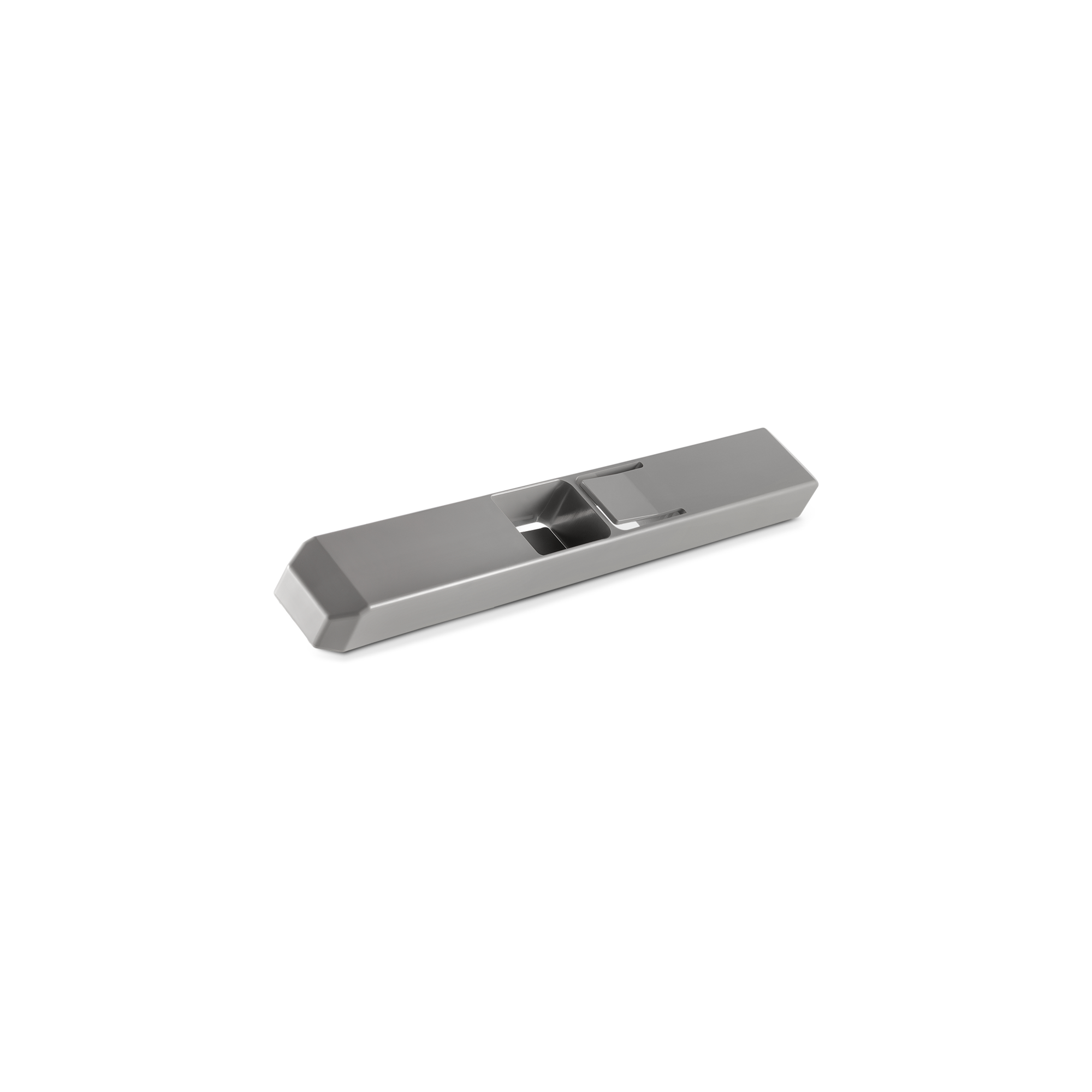

How it works

- Pop off the end cap on the installed Toden Surface.

- Add bracket support for the new section (example: a new 6' section typically uses two brackets when laid out for long spans).

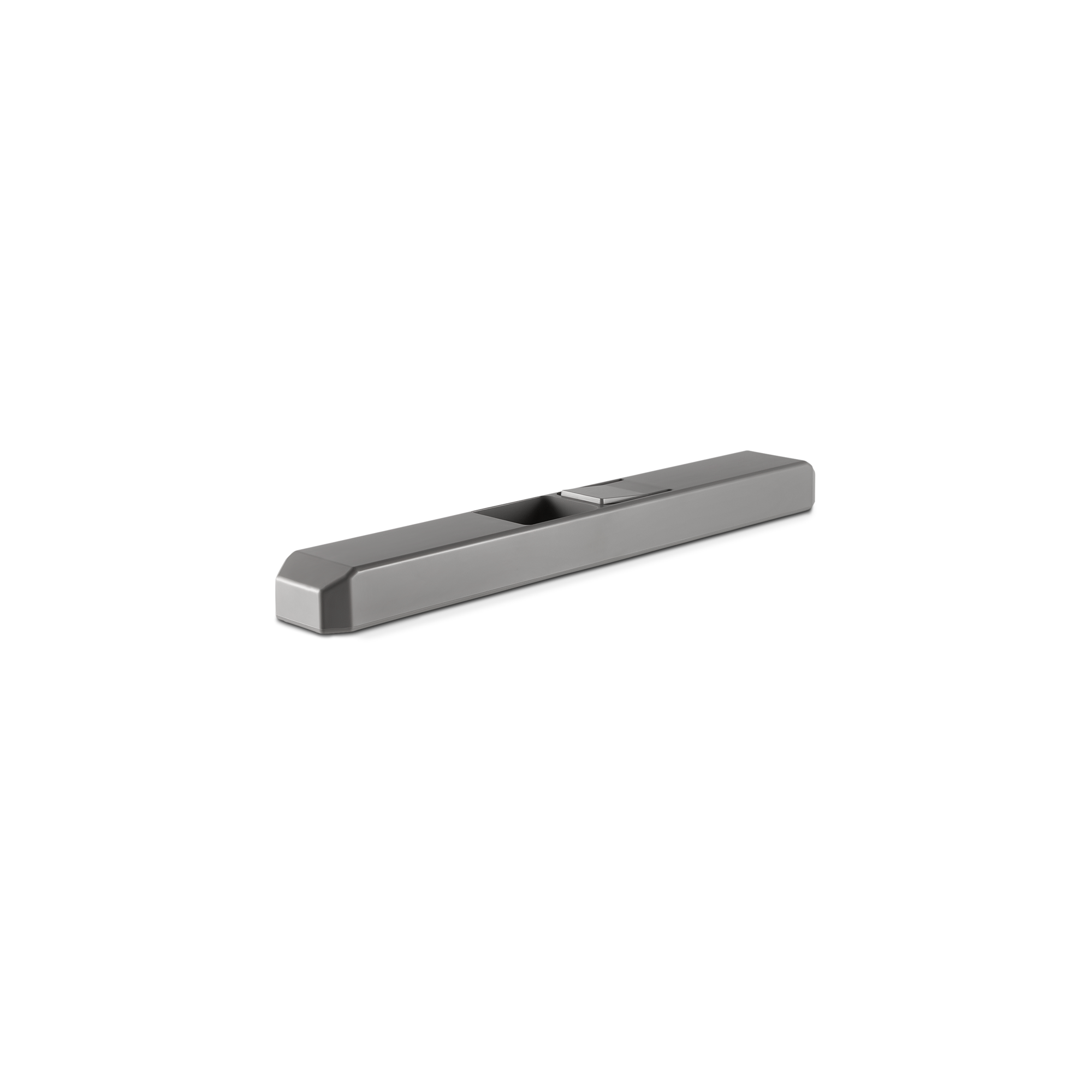

- Slide the Extension Sleeve(s) into the surface’s internal hollow-core cavities until seated.

- Slide the next Toden Surface onto the exposed sleeves to create the joint.

- Reinstall and re-used the end cap for a clean, finished edge.

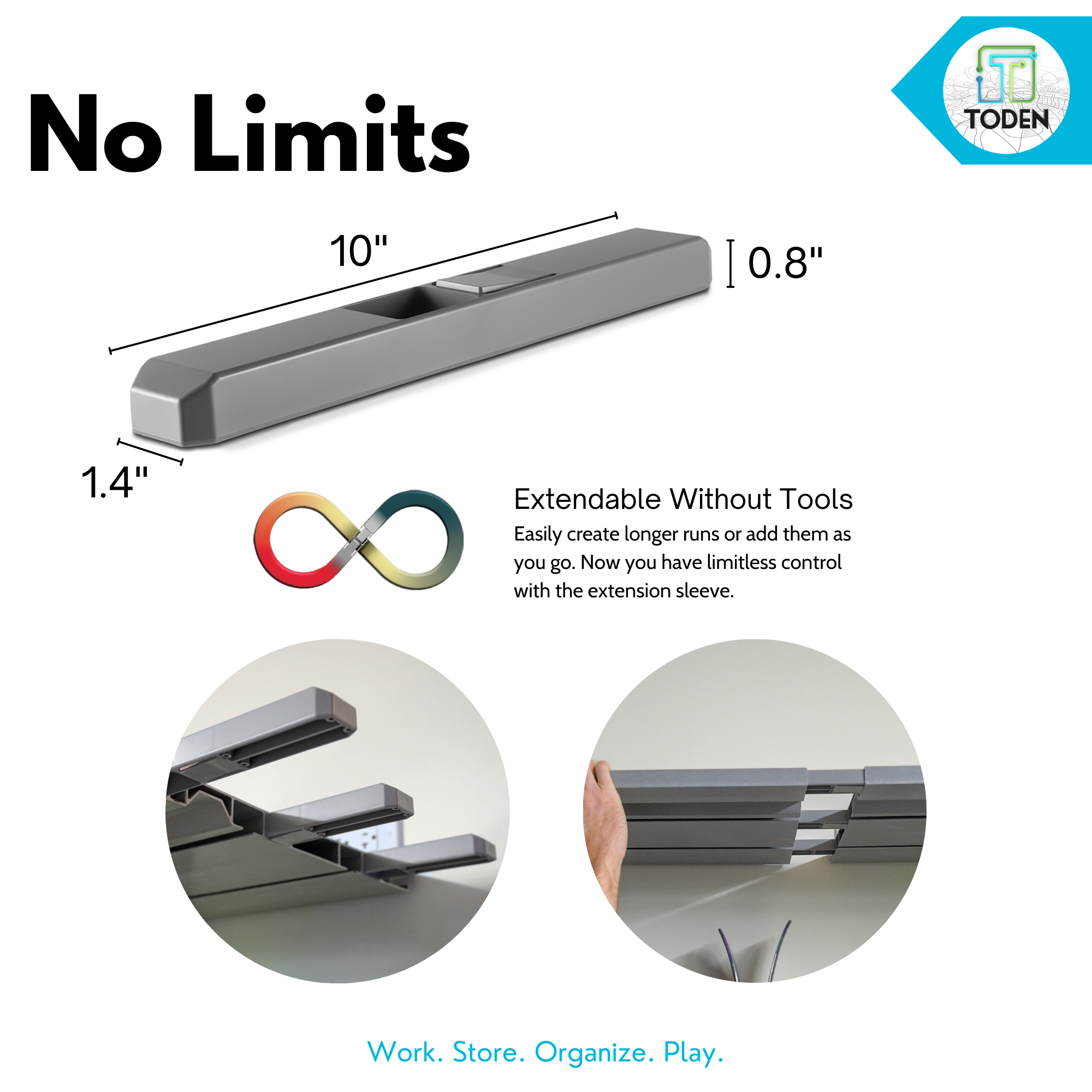

Sizing & system fit

- Fits Toden Surfaces designed with dedicated hollow-core cavities for internal joining.

- One sleeve inserts into one cavity—use one sleeve per cavity at the joint.

- Designed to keep the under-shelf channel uninterrupted, so accessories can still snap in along the run.

- Compatible with Toden layouts that support up to 48" bracket spans and up to 24" cantilevers when installed per Toden guidelines.

**Advanced build hack (internal reinforcement for fasteners and finish nails)**

The Extension Sleeve can also act as an internal reinforcement/backing when you need to fasten custom components to a Toden Surface (examples: steel frames, jigs, fixtures, or project-specific structures). By pushing the sleeve’s internal clip down and positioning it deeper inside the core, you can create a stronger internal “bite point” for fasteners—without relying on thin external brackets or improvised backing.

Note: This is a custom-build technique. You can also use wood as well, here's a video of what this means for a demo. Happy building.

Specs

- Product: Toden Extension Sleeve

- Purpose: Internal connector for joining/expanding Toden Surfaces end-to-end

- Install method: Slide-fit into dedicated surface cavities

- Tools required: None for sleeve installation

- Rated capacity: 300 lb per sleeve

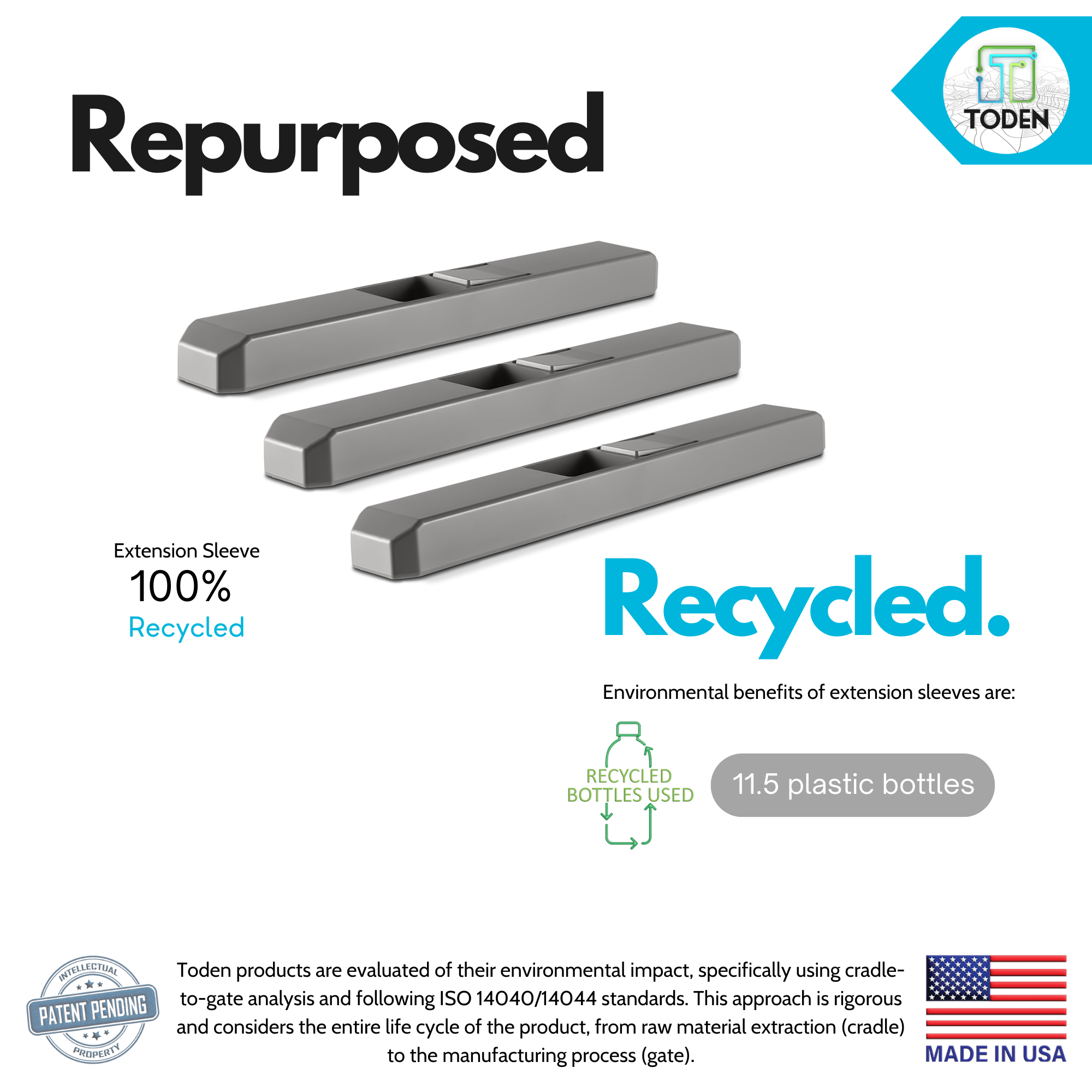

- Material: Engineered and designed for Toden’s modular surface system

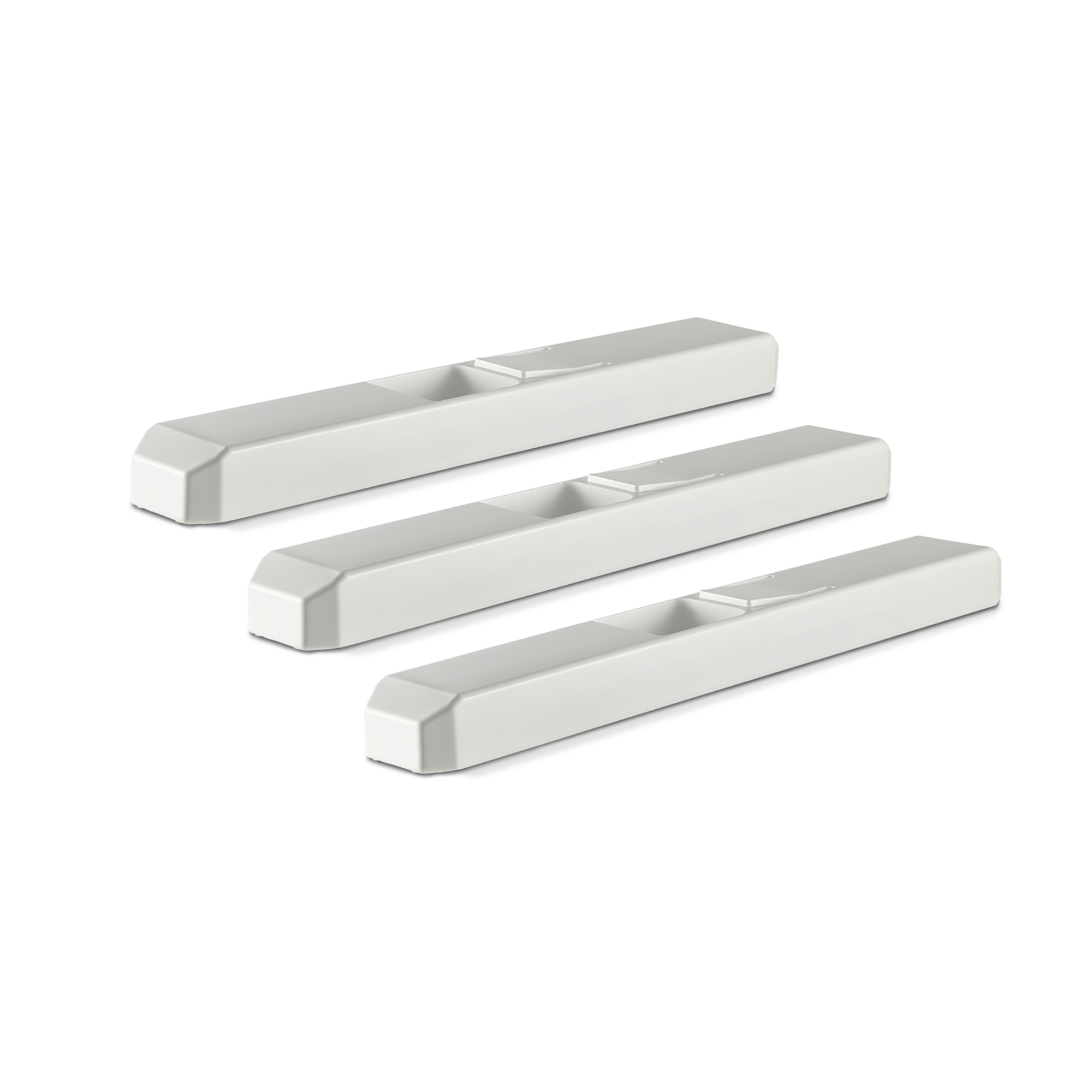

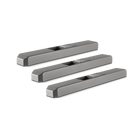

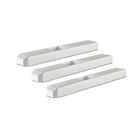

- What’s included: 3 Extension Sleeve(s)

FAQ

Is this only for storage shelves?

No. It’s for extending any Toden Surface run—shelving, workbenches, desks, workspaces, console tables, and more.

Do extension sleeves replace wall brackets?

No. Sleeves join surfaces internally to create rock solid splicing. Brackets still support the run. When you add length, you add bracket supports for that new span, and the brackets can be up to 24" away from the splice. Here's a demo video

Do I need to remove the whole shelf to extend it?

No. You extend from the end: remove the end cap, insert sleeves, slide the new surface on, and support the new section with brackets. You may need to unsnap 2 pins from the bracket closest to the splice but that depends on how wavey the walls are. Definitely don't spend time unloading stuff off the shelf you are extending.

Will the seam be a weak point like a traditional splice?

Traditional splices rely on plates and fasteners and often need a bracket directly under the joint. The Extension Sleeve supports the connection internally and is designed to keep the system performing as intended when installed per guidelines. Also, you don't need a bracket on the splice and can position the next bracket up to 24" away from the splice.

Does it block the under-shelf channel or accessories?

No. The connection is internal, so the under-shelf channel stays usable along the run.

How many sleeves do I need per connection?

Use three sleeves per splice, they precisely fit into the internal hollow-core cavity at the end of the surface you’re joining.

Can I use this to go around corners?

Sleeves are for straight end-to-end runs. For corners, start a new run on the adjacent wall at the same height. The corner mounting solution is really the end cap, you can learn about that product here

Can I use the Extension Sleeve as internal backing for screws/fasteners?

Yes. Beyond joining surfaces, many builders use it as an internal reinforcement: push the sleeve’s clip down and position it deeper in the core to give fasteners a more confident internal anchor for custom attachments (like steel frames or fixtures). This is an advanced use—if you're mounting from the bottom make sure you choose fastener lengths carefully and don’t puncture the top with a fastener that's too long.

You have 30-days to return any item(s) using any of the following methods:

- Shopify self-serve return request

- Email: returns@todenind.com

- Call: (800) 679-1256

Product Benefits & Advantages

Toden products are packed with critical features which are designed to save you time, worry less, and get it done faster.

Product Review

What customers who purchased this product have to say