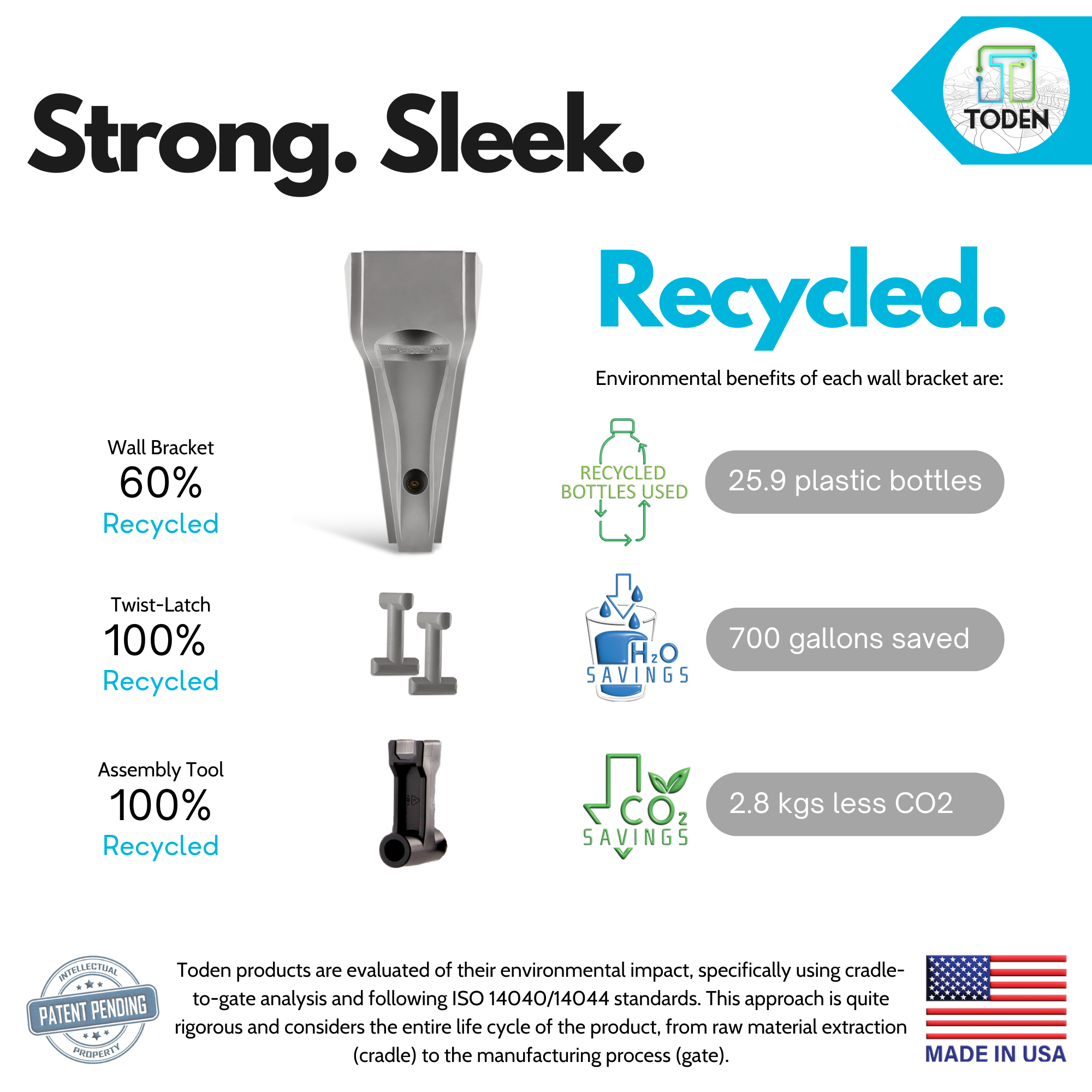

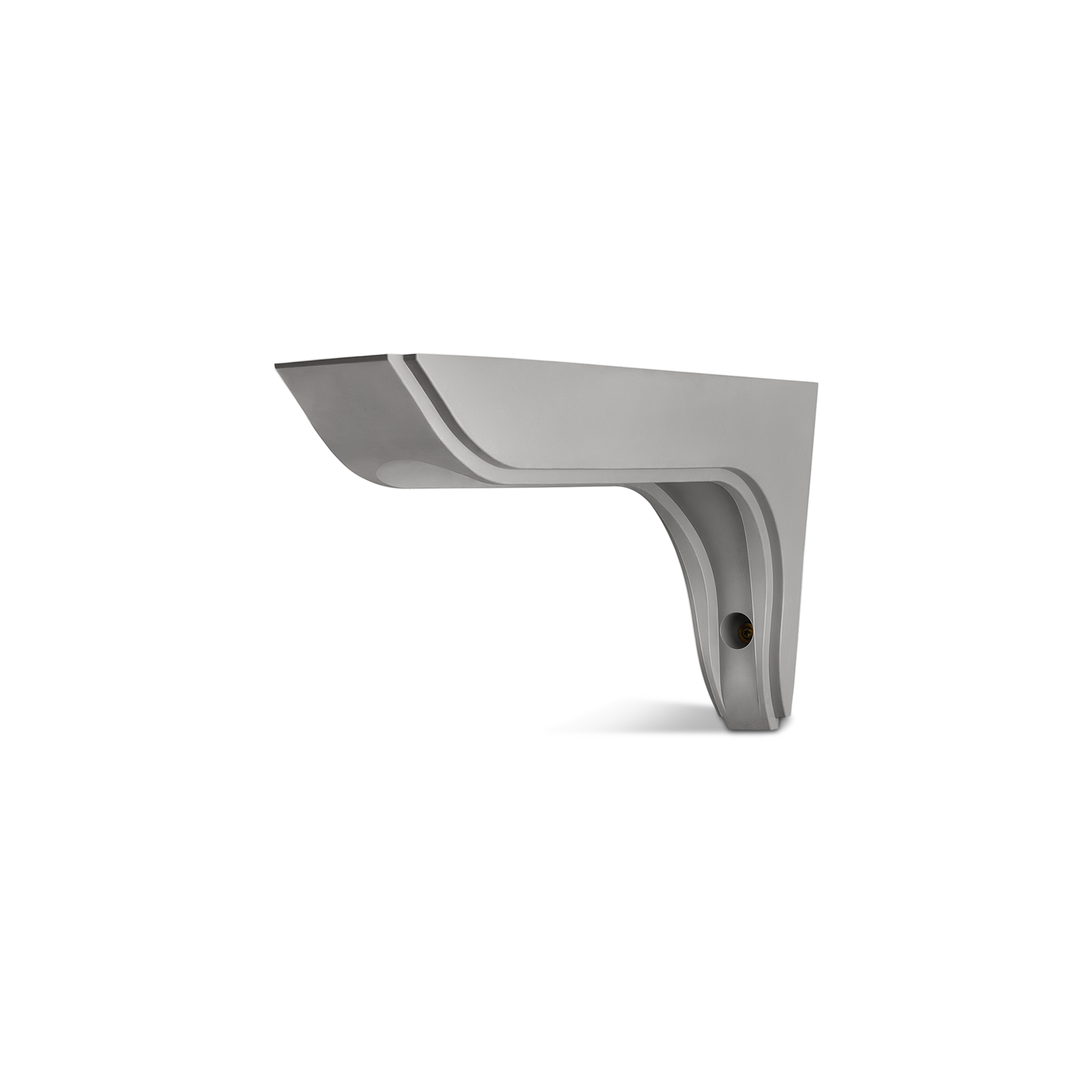

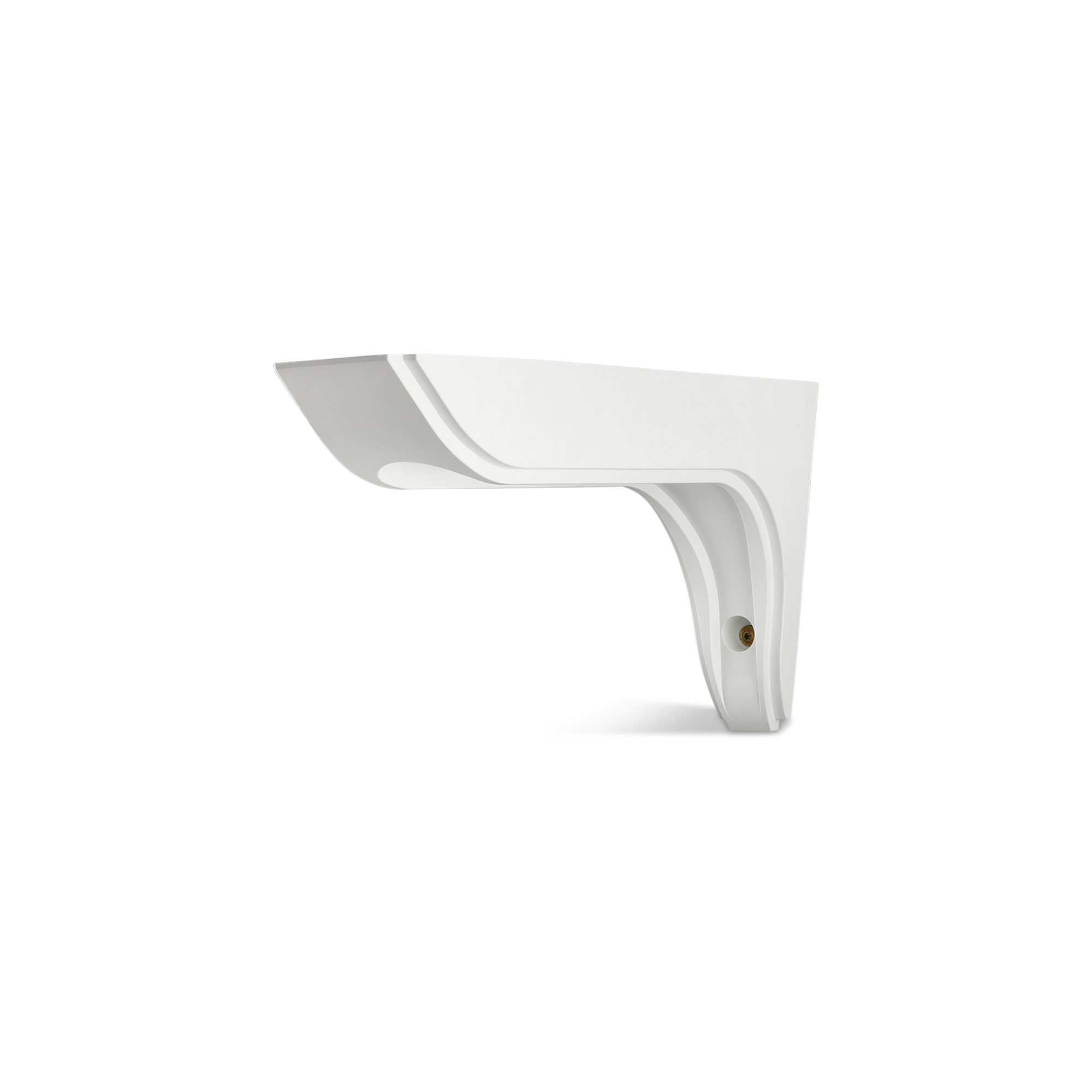

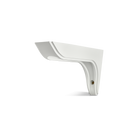

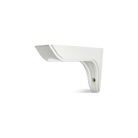

Wall Bracket - 14"D x 7"H

Virtually all shelf brackets are variations of the same idea: metal triangles with a diagonal brace, or simple L-brackets that force you to use a lot of them. The curvature makes it tough to keep your bracket on a level line too, which is obnoxious because these traditional designs require a lot of brackets on the wall, every 16 inches. Whether you're building storage in closets, garages, and utility rooms, both designs create the same pain points: lost usable shelf space, awkward installation angles for screws, and almost always 6 fasteners per bracket. Not to mention that the brackets are so narrow (3/4") wide, joining a shelving splice on one never works well. There's only 3/8" bearing surface, it's zero chill.

Why fewer brackets matters

Traditional brackets typically demand tight spacing and lots of fasteners. That means more measuring, more drilling, more stud misses, and more wall repair if you change your layout later. Toden brackets are designed to span wider and mount cleanly, so you can build a long, level run with less hardware and less rework.

Toden Wall Brackets were designed to remove those problems and it starts with a hypotenuse-free (no diagonal brace stealing space), has a true 90° square back so you can actually line it up cleanly to a pencil mark or laser line. The bracket also includes guided fastener grooves so your drill drives fasteners straight into the wall—no awkward angles, no guessing. The result is a cleaner install with fewer brackets, a slimmer front profile, and serious load capacity for real storage—not “decorative shelf” weight. Now that may sound good, but if you happen to land a splice on a Toden bracket, you get a full 1" of bearing surface to make your shelf splices rock solid and confident.

Use them with Toden surfaces, or use them as the foundation for your own DIY shelf projects. They’re designed with adhesive rails and contact features that support common installation styles when you want to secure stone, metal, or composite shelf materials to the bracket for your own DIY shelf projects.

Key benefits

- No diagonal brace = more usable shelf space (bins and boxes don’t collide with a hypotenuse)

- Square-to-the-line mounting: true 90° square back helps you hold to a level/laser without fighting bent-metal “curves” and eyeballing to get things flat

- Guided fastener grooves help drive screws straight for a solid, repeatable install

- Wide bracket spacing (recommended up to 48" with Toden surface) means fewer brackets and faster layout

- Fewer holes, faster installs: a typical 6' run can take ~18 screws with conventional brackets; Toden can do it with as few as 4 (If your shelf can span 48" like Toden's do)

- Better support for DIY shelving + plywood splices: more practical contact area so you can join shelf panels without adding an extra under-board/cleat just to catch screws

- High load capacity for storage that gets real use, not babied

- Slim, clean look from the front with reinforced ribbing for added strength

- Paintable so you can match the wall, shelf, or trim for a built-in finish look

- Forgiving fit for real walls: supports shimming, and chamfered edges help achieve a clean caulk line if desired.

- DIY-friendly compatibility: designed with surface contact areas/rails for common adhesives when bonding shelf materials of all types

Best uses

- Garage wall shelving runs (totes, tools, bins)

- Closet shelves (linen, baskets, seasonal storage)

- Laundry + utility room storage

- Pantry shelves

- Workshop and mudroom organization

- DIY shelves using wood, composite, metal, or stone shelf materials

How it works

- Lay out your run using a level, use our blue tap tip found in this article.

- Place brackets at your planned spacing (up to 48" where appropriate) and mark fastener locations.

- Fasten into structure (studs or suitable backing) using the bracket’s guided fastener grooves, here's some fasteners by use article

- Set your shelf/surface onto the bracket.

- Optional: secure the shelf to the bracket using your preferred method (mechanical fastening from below and/or common construction adhesives depending on your shelf material and project goals).

Sizing & system fit

- Works as the support bracket for Toden surfaces or as a bracket for DIY shelf builds using common shelf materials.

- Check out this video for how to make a simple plywood shelf with Toden brackets

Specs

- Bracket style: Hypotenuse-free, 90° back (no diagonal brace)

- Recommended spacing: Up to 48" on-center where installation conditions allow or with Toden heavy duty shelves

-

Load capacity: Up to ~1,000 lb per bracket (size/installation dependent)

Always follow Toden instructions and mount into appropriate structure for rated performance. - Finish: Pre-finished but also paintable (accepts common primers/paints)

- Install tools: Drill/driver; level or laser, stud finder

- Wall fit: Shim-friendly; chamfered edges for a cleaner finished look if caulking. Building has gotten pretty sloppy out there, so if your walls are tough, we got you.

- DIY compatibility: Designed with adhesive rail/contact features to support common construction adhesives (adhesives not included)

FAQ

How many screws do I actually need for a 6-foot shelf run?

A typical 6' run with conventional brackets often ends up around 18 wall screws and 18 screws into the shelf - that's 36. With Toden brackets, that same 6' run can be installed with as few as 4 wall screws, with a Toden Surface. Depending on what you're stacking on these bracket will determine your spacing needs and your load plan. Either way you should at least be able to accomplish 24" apart and that would be 6 wall screws and 6 shelf screws. If you're using stone then well adhesive doesn't need screws.

Why is splicing plywood such a pain on normal brackets?

Many standard brackets give you very little shelf bearing width, so joining two wood sections securely usually forces extra workaround pieces—like an under-board/cleat—plus more screws, plus another trim piece to hide the raw edge. Toden brackets are designed to make shelf builds and joins more practical and cleaner-looking with a bracket wide enough to make splices have appropriate bearing surface and attachment for rock solid splicing.

Why do “bent metal” brackets feel hard to line up?

Common metal brackets can have curved profiles and inconsistent contact points that make them annoying to hold perfectly to a mark or laser line. Toden’s square back geometry is made to register cleanly and stay where you put it.

Do these only work with Toden surfaces?

No. They’re designed to support Toden surfaces and DIY shelf builds using common shelf materials.

Why is “no diagonal” such a big deal?

Diagonal braces steal usable shelf area and block bin placement. A hypotenuse-free bracket keeps your entire horizontal shelf plane usable without dead spaces.

How far apart can I space the brackets?

Toden brackets are designed for wider spacing than typical market brackets—up to 48" with Toden Surfaces. If building your own shelf or using other materials then bracket spacing should follow where installation conditions and load plans allow. Heavier loads may require tighter spacing of wall brackets.

Are they hard to install?

They’re designed to be straightforward: a true 90° back references cleanly to a level/laser, and guided fastener grooves help drive fasteners straight into studs or concrete.

Can I paint them to match my space?

Yes—these are designed to accept commonly used primers and paints.

Can I remove them later (renters / future changes)?

Yes. A mechanically fastened bracket system can be disassembled and moved, which helps preserve your investment when layouts change or if you change homes.

You have 30-days to return any item(s) using any of the following methods:

- Shopify self-serve return request

- Email: returns@todenind.com

- Call: (800) 679-1256

Product Benefits & Advantages

Toden products are packed with critical features which are designed to save you time, worry less, and get it done faster.

Product Review

What customers who purchased this product have to say